written and photographed by John Riha

The Rogue River is an Oregon treasure, brawling its way through 215 miles of rocky chasms and rolling valleys, renowned for runs of salmon and steelhead that bring fly-fishing aficionados from all over the world.

It’s not surprising, then, that the Rogue has also attracted some of the most talented fly-fishing gear-makers in the Northwest, artisans whose creations blend artistic style with incredible performance.

Precision Engineering

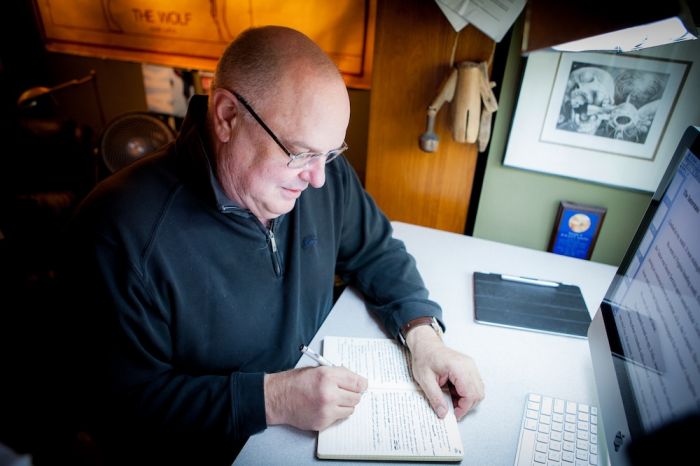

Bob Meiser began building rods when he was a kid in Wisconsin, rifling through the trash bins of a local rod-making company for parts to cobble together his own “custom” fishing rods. Through stints in the military and a move to the Pacific Northwest to become a renovation contractor, those childhood impulses never left him. Today, he builds fly rods of sublime grace and beauty in his Central Point shop, creating some 400 rods per year for discriminating clientele who appreciate the quality of the R.B. Meiser Fly Rods brand.

Although Meiser specializes in two-handed spey rods favored for fishing steelhead on the big rivers, he can make virtually anything. So precise is his methodology that clients can give Meiser the name of the river they intend to fish, the time of year and the intended fish species, and he’ll build a rod specifically to match

that criteria.

“It’s very targeted engineering,” Meiser said. “We use science to create rods that are poetic and lethal.”

Engineering notwithstanding, Meiser knows matching a rod to a fly-fishing enthusiast can be more art than science. “It all comes from your gut,” he said. “All fishermen inherently have the ability to recognize a rod action they prefer, and everyone is different.”

A Vietnam vet, Meiser has worked with Project Healing Waters and other veterans’ help groups to build specially designed rods for those with prosthetics and other limitations, often donating rods and commissions.

Finely Tuned Machines

Jon Bauer is a Trans-Am Champion race car driver who turned his love of race cars into building finely machined fly-fishing reels. With tolerances that are fractions of a human hair and spectacular anodized finishes, Bauer fly reels are the gold standard. His patented concept of a large-arbor reel and one-way clutch has revolutionized the fly-reel industry. A relentless innovator, Bauer has a passion for continued improvements fueled by building better and better race cars. “I’m not influenced by what’s been done before,” he said, “and I love precision.”

Bauer grew up in Southern California where he fished in Santa Barbara Harbor as much as he could. Eventually, he took to fly-fishing in the trout streams of the Sierras and “never picked up a spinning rod again.”

As his career as a driver wound down, Bauer took to high-end-spec machining and started to tinker with fly-reel design on the side. In the early 1990s, his love of fly-fishing and backpacking trumped his desire to be in the race-car business, and he and his wife moved to Ashland to raise their daughters in a healthy community and be close to the clear, clean rivers of Southern Oregon.

Although Bauer recently sold his business to Winston Rods in Montana, Bauer-branded reels are still manufactured and designed in Southern Oregon using the same tolerances and precision specifications.

A Family Tradition

Southern Oregon natives Bill Bittle and his son, Ryan, began building wooden landing nets three years ago after Bill retired as a carpenter and furniture-maker. The time was right, they decided, for turning their shared love of fine woodworking and fly-fishing into an entrepreneurial father-son venture.

“My dad taught me how to fish,” Ryan said, recalling trips to Lake of the Woods and nearby mountain lakes. “Eventually we got into swinging flies. Growing up, I was always hanging around his shop at home and loved handmade stuff. So building wooden landing nets was just a natural combination for us.”

The Bittles’ business, PNW Landing Nets in Medford, makes landing nets as tough as they are eye-catching. Each is made of walnut and maple that Bill Bittle handpicks with a critical eye for straightness and grain pattern. Strips of the woods are steam-bent and laminated to form rims and handles featuring striking bands of dark and light wood. The laminate construction gets an extra boost of strength from a waterproof glue that Bittle designed himself specifically to hold up in harsh outdoor conditions.

“It’s tough as steel,” Bittle said, “and 100 percent waterproof.”

The nets are sealed and finished with seven coats of polyurethane, each coat sanded glass-smooth with 500- to 600-grit paper before the next coat is applied. The Bittles strive for a flawless aesthetic, and each of the more than 150 nets they send out the door annually is meticulously checked for the slightest defect. A fish-friendly rubber net bag completes each gleaming landing net.

“They’re guaranteed for life,” Bittle said. One of the special things about the business is getting to work with his son. “It’s very enjoyable,” he said. “We’ve always shared the same interests.”