interview by Ben McBee | photos by Thomas Boyd

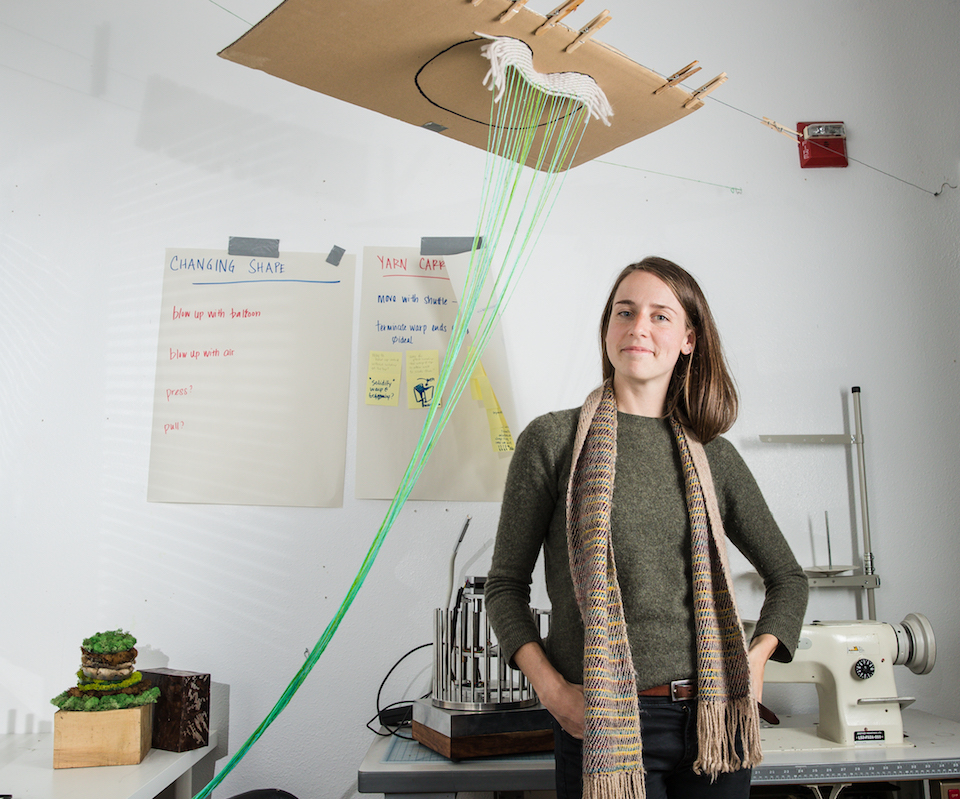

Think about the clothes you’re wearing. How much of the material used to make them actually ended up on the factory floor as excess, cast aside and thrown away? Beth Esponnette, a Bay Area entrepreneur turned University of Oregon professor, is tackling wasteful clothing manufacturing practices with research that incorporates weaving with 3D printing. Originally from Maine, Esponnette earned her MFA at Stanford University and quickly set to work on her startup, unspun, with the mission of modernizing what she considers an outdated industry standard. She now teaches in UO’s Product Design program while continuing to develop her company.

3D printing has led to innovations in many fields. How can the technology revolutionize traditional clothing production?

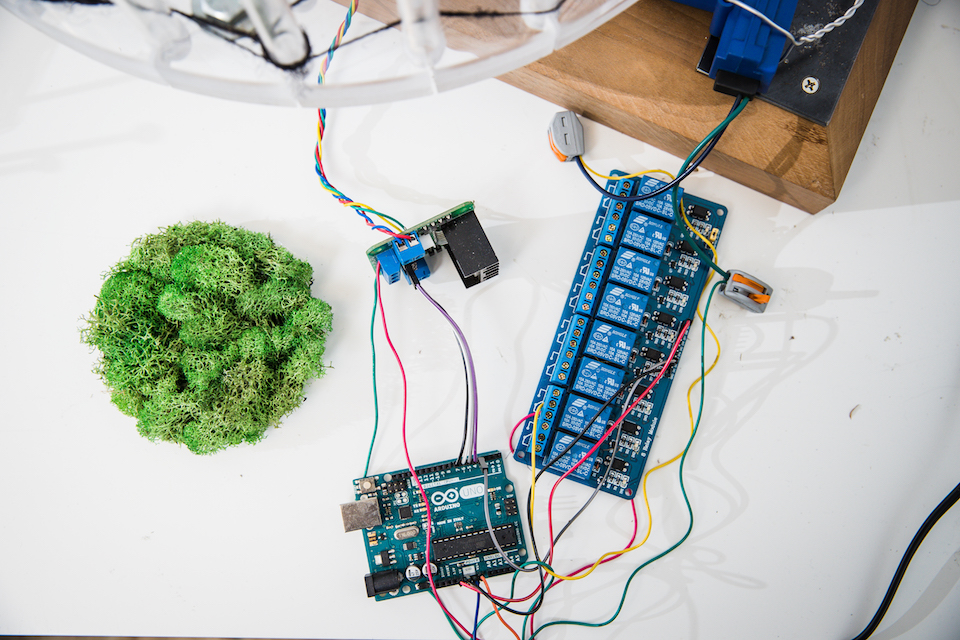

Traditional clothing manufacturing is done with a subtractive process. In order to make a two-dimensional fabric into the piece of clothing that you want, you need to cut it apart, which damages it, and then you need to re-adhere it back together with stitching. There is a lot of waste involved in the cutting part and seams are problematic because that’s where things break apart or let water in. A way to make manufacturing additive is to basically skip the cutting and sewing step, so you’re no longer using the fabric stage. We’re trying to go straight from yarn, into the final product, so that you have no waste.

What are the functional benefits of 3D-printed clothes?

In general, 3D-printed clothing is going to be a lot stronger because there are no breakage points, which are the places where the products fail, essentially. Also the thing that consumers usually care most about is the comfort, and seams are where people feel discomfort because it’s extra material that will chafe against their skin, or add extra weight and bulk that they don’t want.

3D printing also provides the opportunity to create customized products, because you’re boiling all these processes down into one step, essentially. You don’t necessarily need humans in the equation either. When you break down something into machine code, you can think about having measurements and data straight from your consumer, that (you) can then put into this machine and create a garment right on the spot. Every product that comes off the printer can be altered in some way. It would be the same with this kind of clothing.

Oregon prides itself on being green and efficient with its resources. Has moving here inspired you in any way?

It has strengthened my desire to help fix some of the problems in manufacturing. I live near Hendricks Park in Eugene, and it’s beautiful and green. My house is surrounded by trees, and it reminds me of where I grew up in Maine. With bad news every day, more and more proof that global warming is an issue, being around Oregon and seeing that we still have beauty here to save has been very inspirational.