The top entrepreneurs and innovations in our great state

written by Kevin Max, Lindsay McWilliams and Sheila G. Miller

Oregon is no place for the faint of heart. Those who live here survive and thrive and pave the way. When we see a problem, we fix it. We innovate, we challenge, we persevere. And so it is no surprise that people all over this state are launching new ideas and seeing through plans to make the world a better place. Here, we look at a few of their big ideas.

ARTS

Hollywood Theatre @PDX

Your layover in Portland International Airport’s C concourse just got a lot less dull.

Thanks to a collaboration between NE Portland’s historic Hollywood Theatre and the Port of Portland, travelers will be able to cozy up to an hour’s worth of local filmmakers’ short films in a free, eighteen-seat theater.

The theater’s executive director, Doug Whyte, got the idea after reading an article about an airport movie theater abroad. “PDX should have one,” he thought.

He approached the Port of Portland, and it turns out its employees had long held a similar dream. The Port offered up a little-used, outdated business center at no cost. Hollywood Theatre grabbed grants from the Oregon Community Foundation, Oregon Cultural Trust, Travel Oregon and others, and received donations from companies like Triad Speakers, which provided a $50,000 surround sound speaker system for free. As a result, the project became loftier—it’s now essentially the highest-end home theater system available.

The theater will break all kinds of barriers at the airport. For starters, the Port of Portland generally outlaws neon, but in this case the theater marquee will light up the concourse as an art installation.

The theater will not show full-length feature films, in part because most layovers aren’t conducive to it. Instead, it will feature pieces mostly less than five minutes, which Whyte has been collecting for more than a year. All of the work will be made by local filmmakers. And because of Port policies and the openness of the project, the films have to be G-rated (“That was a challenge. Independent filmmakers have dark minds,” Whyte said). Portland State University film students submitted work, as have some animators in the community. The theater will also feature music videos. The theater will run the short pieces in an hourlong loop, and change out the content every quarter.

“It’s the perfect thing when you’ve got time to kill,” Whyte said. “You can sit down and watch in a group setting. We’ve already had other theaters from around the country approach us about how to do this.”

Ultimately, Whyte hopes to see the space host even more unique events—perhaps beer tastings or live music.

GREEN LIVING

Tiny Home Designer

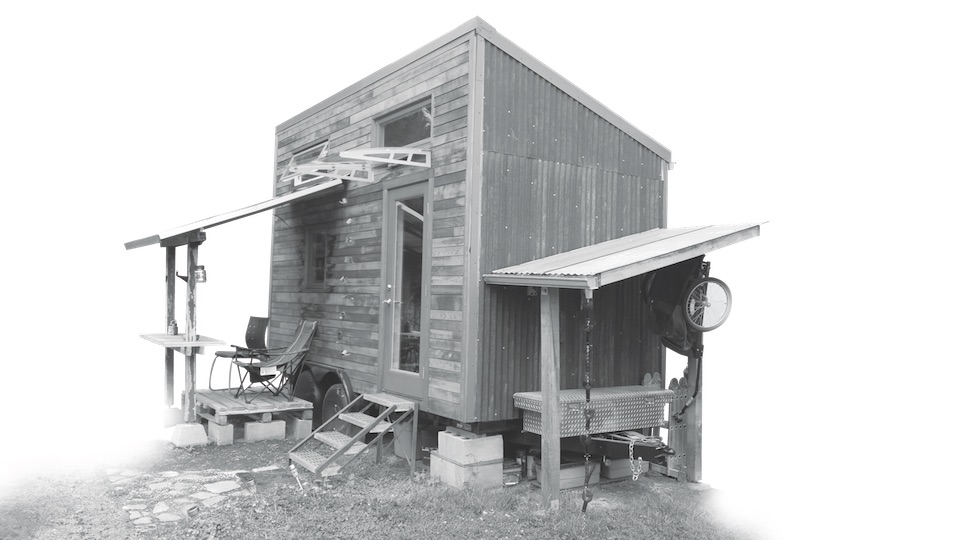

Often, necessity is the mother of invention. Such was the case with Laura Klement’s

Klement began creating a professional portfolio of experience that is well suited for the complex task of tiny home design and building. She had a degree in architecture, took jobs in natural home building, installed solar panels, took courses at Vermont’s Yestermorrow design/build school and learned the rudiments of electrical wiring.

Though the farm girl from Minnesota would never consider herself an entrepreneur, her ability to learn and innovate is on par with the best.

“This was a project for me,” she said. “Being able to put a lot of craftsmanship into your own home means a lot.” Klement also blogged her trials and tribulations (lauraklement.blogspot.com) to a growing audience of tiny home aficionados. In her blog, she documents such topics as considerations for a solar awning to new ideas in toilet technology.

Last September, Klement moved her tiny home from Portland to the rural reaches of Mosier, where she is studying to teach yoga, among other things.

Tiny homes have an outsize Pinterest appeal, no doubt. What’s not pictured, Klement noted, is reality. Weather, for example is a factor in a home that is scarcely larger than some SUVs. “I wish I would have thought out the shower more,” she said. “Moisture and ventilation can be an issue in tiny homes.”

FURNITURE MAKERS

A New Kind of Comfort

The goal of Jason Rens’ furniture is not to make inhabitants “comfortable”—at least not in the traditional sense of the word.

“I think of comfort in a more imaginative way,” said Rens, a designer and furniture maker in Portland, whose brand is titled Rason Jens. “I want someone to be comfortable in their home because it inspires them or is playful.”

Rens creates custom pieces for homes, commercial spaces and for art’s sake. In 2015, his works were included in an exhibit at the Bellevue Arts Museum. He’s worked with big Oregon names such as Nike and continues to do commissions with Salt+Straw, Portland’s beloved ice creamery.

After studying architecture at University of Colorado, he went on to join the woodworking program at the Oregon College of Art and Craft in 2007 where he focused more on furniture design. In 2010, he founded SuperMaker, a collaborative studio space of designers and makers in Southeast Portland.

Highly angular and geometric, using experimental materials like flocking fibers and spray-on rubber, his works resemble more modern artwork than traditional furniture—the kind you stop and stare at for a time. He likes it that way. He believes the objects we live with should have depth and induce contemplation.

ATHLETICS

Making Gear for Oregonians

Oregon is above California. Not only a helpful reminder, but also a subtle dig at the changing demographics of our state. And who’d have thought the slogan would come from a

That’s exactly what’s happening at Grafletics, where Rick Gilbert is tapping into the Oregon psyche with his tees, hats and other clothing that tugs at our sports soul.

“It’s the biggest compliment that people give me, not just me but the product line itself,” Gilbert said. “I tell people I came from Baltimore and they’re like, ‘What?’ Because a lot of people feel we’re really representative of the area.”

Gilbert started visiting a long-lost great uncle in Portland in 2002. By the time Gilbert relocated to Portland in 2010, he understood our history. He combined his adoration of athletics (basketball is his first love), his talent as a graphic designer and his interest in the region—and Grafletics was born.

What started as a part-time lark in December 2013 has morphed into a huge business. From 2014 to 2015 the company’s revenue grew by 340 percent. 2015 to 2016? Another 143 percent.

He credits his success with his adopted hometown’s love of sports.

“I quickly realized what a special place Portland is and Oregon is for the sport of basketball. It’s extremely unique when you come from somewhere else. On the East Coast you’ve got every single sports team you could imagine, and their markets are an hour away from each other. … Here the Blazers are the main game in town, and I think that trickles down.”

His first graphic, the Game On graphic, was an homage to that—the state of Oregon with the basketball’s channels running through it. Gilbert started with basketball, then got turned on to soccer and designed a collection devoted to that.

His work has since morphed to include lifestyle-themed pieces as well, with Mt. Hood and Haystack Rock and the PDX carpet. Next up Grafletics will feature children’s sizing in its spring line, and is doing a locals line with the Portland Trailblazers and a collaboration with the Portland Timbers. The company is also starting a customs program, working behind the scenes to launch and promote other brands.

“(Our work is) being adopted by people who have deep roots here, who are from here and either love it and are living here, or love it and have moved somewhere else. It gives me a lot of satisfaction that this stuff we’re making is resonating with people on a deep level.”

AGRICULTURE

Oregon State University’s Plant-breeding and Genetics Program

OSU has long operated a strong agricultural sciences school, and different parts of the school have conducted plant breeding and genetics studies. But about five years ago, the various groups got together to start offering a program

“The ultimate goal and the methods and tools that we use for breeding are all the same,” John Henning, a professor who specializes in hops breeding, said. “So even though someone working in forestry breeding may take fifteen to thirty years before they get a new tree released … and hop breeders take anywhere from twelve to fifteen years, we’re all doing the same thing.”

The departments banded together and developed the program to focus on courses that undergraduate and graduate students would need to specialize in breeding and genetics.

The program depends, primarily, on growers coming to the university and asking for help, Henning said. “It’s driven by commodity. Groups say, ‘This is what we want,’ and OSU responds by developing and hiring someone with the capability to do that kind of work.”

The program is working on a variety of scientific developments, including green beans resistant to white mold and hazelnuts resistant to Eastern Filbert Blight, as well as high-yielding potatoes to help prevent hunger.

Now, Henning said, scientific advancements are coming at the molecular level. The program is moving from traditional plant breeding, in which a scientist would grow cross-bred plants in a field, then make field-based assessments. Now, breeders are using molecular markers tightly linked to traits to make selections. For example, if a scientist seeks disease resistance, she would identify the molecular markers most closely linked to that trait, then grow plants with those markers in a greenhouse to check that resistance.

“By using molecule markers we’re taking a whole step out of the breeding process,” Henning said. “It’s speeding things up and speeding up the accuracy.”

WOOD PRODUCTS

A New Source of Sustainable Energy

“Oregon has forests, and we thought we could use them to come up with clean replacement technology,” Morihara said.

His company, HM3 Energy in Gresham, takes excess forest slash (which is usually burned and discarded) and agricultural residue, roasts it at 400 degrees, grinds it, forms the powder into briquettes and treats the briquettes with water-resistant technology. In simpler terms, forest waste is turned into a source of energy—a source that produces far less greenhouse gas than coal.

With this technology, licensed in 2015, Morihara hopes to move into the clean energy market in the next year or two. Four companies have already purchased licensing, including New Energy Development in Japan.

“We believe in this technology and we’d like to make it available all over the world,” Morihara said.

WILD CARD

Young Animators In the Making

Zing, a toy company based in Portland, has developed a hands-on activity for creative young min ds—StikBot. Stikbots are tiny, robot-like figurines that come in many colors, bend in multiple places and have suction cups for hands and feet. After downloading the free StikBot Studios app on a smartphone, children have all they need to make their very own stop-motion animation film. The app directs users to take numerous photos of the StikBots, adjusting them just slightly each time. When all of the photos are put together, it creates a video with more fluid motion. The app is extremely user-friendly for kids and even allows them to add sound effects to a video or record their own.

StikBot can also be purchased with accessories, such as a green screen to add fun backdrops to each scene, a tripod to hold the phone steady while filming or clothing and hairstyles for the StikBots.

More than just a video game or television show, StikBot requires kids to actively participate in the production of their own video, with opportunities to improve and reach a more complex level of filmmaking.

CONSTRUCTION

Cross-laminated Timbers

The college graduate had worked summers at the family business but never considered it a long-term career for a young woman. “It was man’s work, and my dad was strictly a traditionalist … though I don’t know that I bought into that,” said Johnson, reflecting on her decision with a laugh. “Dad actually tricked me into it. He was a persuasive character.”

In 2006, the elder Johnson suffered a debilitating stroke, and his daughter, who had worked her way up through the family company, stepped in to a leadership role at DR Johnson Lumber Co.

In 2013, Johnson attended a meeting that would impact the direction of DR Johnson and building in the United States. The dean of Oregon State University College of Forestry, Thomas Mann, was looking for a willing partner to test and measure a new trend in structural laminated wood that he had seen in Europe. Johnson stepped up. “How hard could that be?” she asked herself.

It took some arm-twisting back in Riddle, but her mill team had soon re-engineered equipment and processes to create 10-foot-by-10-foot cross-laminated panels. Cross-laminated timbers, or CLTs, are wood panels consisting of layers of wood glued at right angles to form structural panels, now seen as a more environmentally friendly substitute for concrete.

In 2014, DR Johnson became the first company in the United States to earn certification for CLTs. Projects started flowing. Immediately, CLT became foundational to Portland’s Albina Yard building; a twelve-story building in The Pearl District; a rebuild of Oregon State University’s Peavey Hall and, now, interest coming from Silicon Valley.

“We really are a healthy upgrade from the current ways of commercial building,” Johnson noted.